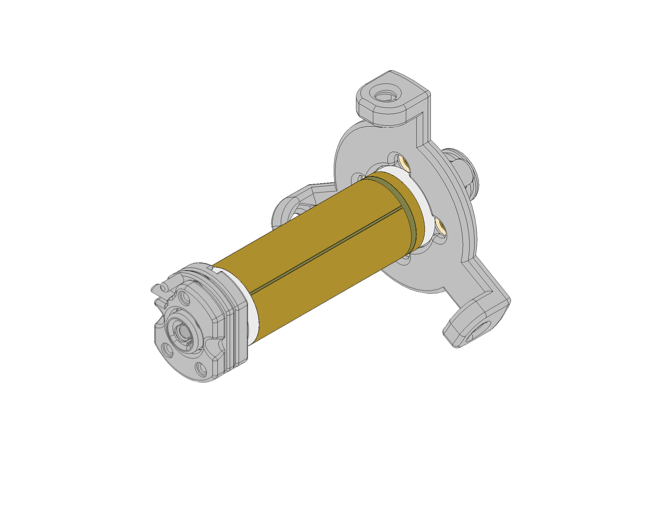

Piezo assembly

19/Apr 2017

(Note, 8/6/2020: We’ve moved away from this design, because the epoxy connection between the bottom piezo cap and the silver base invariably broke when cooling the microscope down to 77 K.)

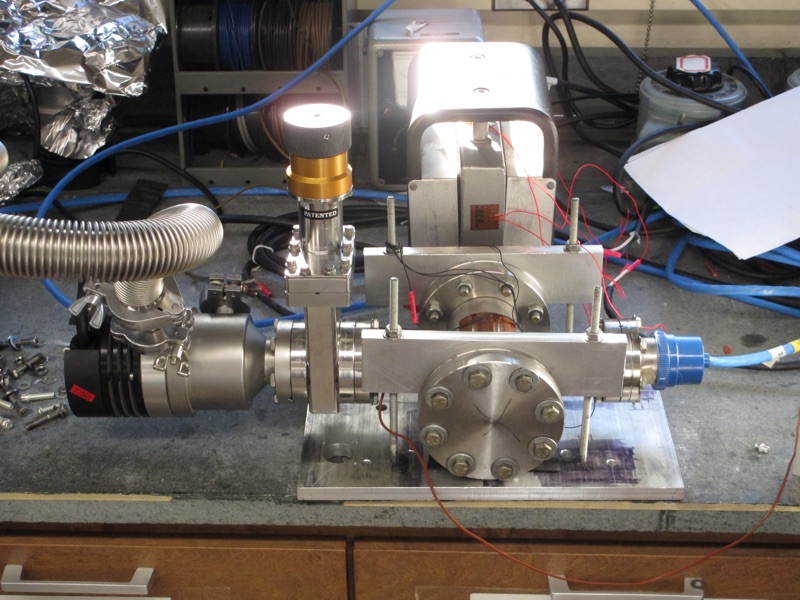

This is the single-tube STM scanner design currently in use in the Kandel lab. The tip sits in a carrier made from 1/16” OD capillary tube, and the tube rests on four ball bearings that are press fit into a metal frame. Coarse motion then comes from inertial slip-stick cycles driven by the scanning piezo.

Three thumb screws around the perimeter of the base are used for initial alignment of the scanner in the XY plane, relative to a larger ceramic tube that supports the scanner assembly. Mechanical stability comes from a fourth set screw tightened along the Z (piezo tube) axis.

All metal parts can be 3D-printed. Other parts include:

- 0-80 screws and small-pattern nuts, 1/16” tungsten carbide balls, and 1/16” capillary tube, all from McMaster-Carr.

- Ceramic hat washers from Mcallister Technical Services.

- Sapphire ring jewels from Swiss Jewel.

Autodesk Inventor and Eagle files are here.

STL files (for 3D printing) are here.

(Assembly instructions coming soon.)